Zinc Oxide Spray Paint

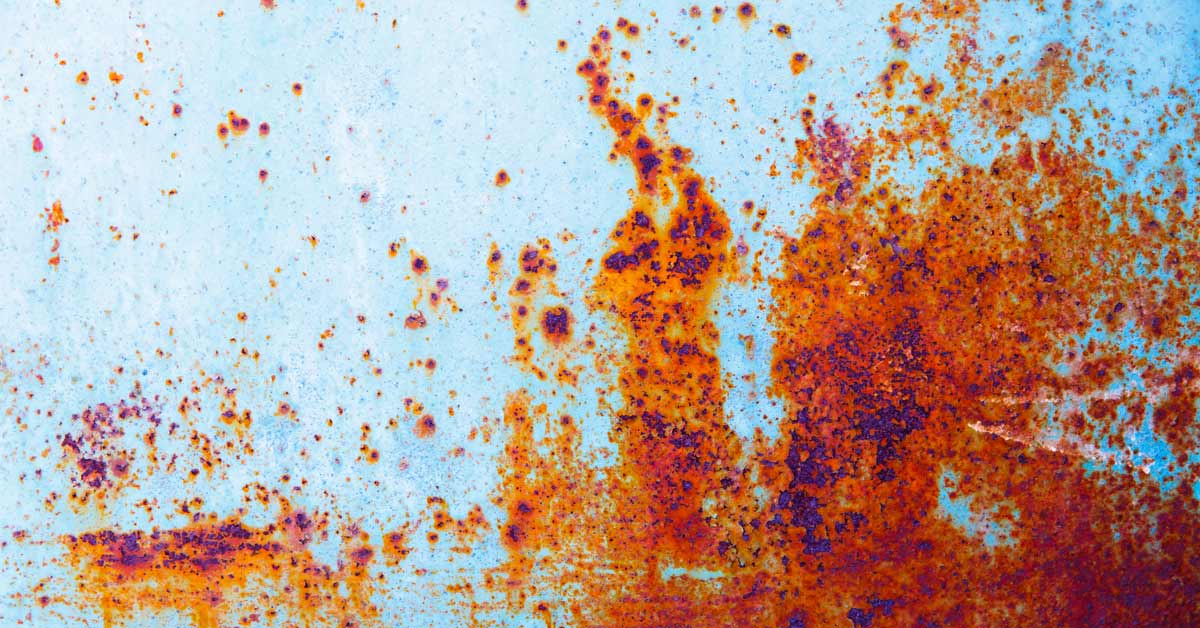

Zinc oxide spray paint. Hot-temperature black-oxide processes produce glossy black-blue coatings and true black-oxide magnetite finishes in 1020 minutes. To help architects engineers and other specifiers assess and select the most suitable zinc coating for corrosion protection. Iron manganese and zinc phosphate finishes provide extensive corrosion protection and prepare surfaces for a strong paint bond.

3 4 6. EPi offers all three black oxide processes. Zinc oxide nanoparticles ZnO NPs are used in an increasing number of industrial products such as rubber paint coating and cosmetics.

3 5 and Outside System No. Metallized Hot-Dip Galvanized Zinc Paint Galvanized Sheet Electroplated 1 mil Figure 1. Series 91-H2O uses a zinc pigment which meets the requirements of ASTM D 520 Type III and contains less than 002 lead.

Meets zinc-rich primer requirements of AWWA D102-17 Standard for Inside System No. Zinc painting zinc spray metallizing mechanical plating electrogalvanizing and zinc plating. PERFORMANCE CRITERIA Extensive test data available.

Powerful corrosion-resistant sealers with exceptional salt spray protection are used over zinc-plated passivations. Cathodic Protection from Zinc. EPis line of high-temperature blackeners offers impressive abrasion and corrosion resistance and several.

In the past two decades ZnO NPs have become one of the most popular metal oxide nanoparticles in biological applications due to their excellent biocompatibility economic and low toxicity.

Metallized Hot-Dip Galvanized Zinc Paint Galvanized Sheet Electroplated 1 mil Figure 1.

Zinc oxide nanoparticles ZnO NPs are used in an increasing number of industrial products such as rubber paint coating and cosmetics. Powerful corrosion-resistant sealers with exceptional salt spray protection are used over zinc-plated passivations. EPis line of high-temperature blackeners offers impressive abrasion and corrosion resistance and several. 3 4 6. Hot-temperature black-oxide processes produce glossy black-blue coatings and true black-oxide magnetite finishes in 1020 minutes. Meets zinc-rich primer requirements of AWWA D102-17 Standard for Inside System No. In the past two decades ZnO NPs have become one of the most popular metal oxide nanoparticles in biological applications due to their excellent biocompatibility economic and low toxicity. Series 91-H2O uses a zinc pigment which meets the requirements of ASTM D 520 Type III and contains less than 002 lead. Cathodic Protection from Zinc.

EPis line of high-temperature blackeners offers impressive abrasion and corrosion resistance and several. Zinc oxide nanoparticles ZnO NPs are used in an increasing number of industrial products such as rubber paint coating and cosmetics. Meets zinc-rich primer requirements of AWWA D102-17 Standard for Inside System No. In the past two decades ZnO NPs have become one of the most popular metal oxide nanoparticles in biological applications due to their excellent biocompatibility economic and low toxicity. Powerful corrosion-resistant sealers with exceptional salt spray protection are used over zinc-plated passivations. Series 91-H2O uses a zinc pigment which meets the requirements of ASTM D 520 Type III and contains less than 002 lead. Hot-temperature black-oxide processes produce glossy black-blue coatings and true black-oxide magnetite finishes in 1020 minutes.

Post a Comment for "Zinc Oxide Spray Paint"